Imagine being able to power a wide range of tools and machines with just one device. That’s the magic of air compressors, a tool that can revolutionize the way you work and play.

Whether you’re into DIY projects or run a professional workshop, understanding the different types of air compressors can unlock new possibilities for you. Think about the efficiency, speed, and versatility that a well-chosen air compressor can bring to your tasks.

But here’s the catch: choosing the right one can be overwhelming with so many options available. You might wonder which type is best suited for your needs, or how each one functions.

This article is here to clear up the confusion and guide you through the maze of choices. By the time you finish reading, you’ll feel confident in picking the perfect air compressor to boost your productivity and creativity.

Let’s dive into the world of air compressors and discover which type is your perfect match.

Reciprocating Compressors

Reciprocating compressors are the workhorses of the air compressor world, known for their reliability and versatility. If you’ve ever worked on a DIY project or in a garage, you might have used one without even realizing it. These compressors use pistons driven by a crankshaft to deliver high-pressure air, making them suitable for various applications, from powering pneumatic tools to inflating tires.

Imagine the rhythmic motion of a piston moving up and down; that’s essentially what’s happening inside a reciprocating compressor. It’s a simple yet effective mechanism, and understanding its types can help you choose the right compressor for your needs.

Single-acting

Single-acting reciprocating compressors operate with a piston that compresses air only on one side. This design is straightforward and often found in smaller, portable models. They’re perfect for light, occasional use, such as inflating a bicycle tire or a basketball.

Single-acting compressors are typically more affordable and easier to maintain, making them a great choice for hobbyists and small business owners. However, they might not provide the power needed for heavy-duty tasks. Have you ever thought about how choosing the right type can affect your project outcomes?

Double-acting

Double-acting compressors take it a step further by compressing air on both sides of the piston. This design doubles the efficiency, providing more power and faster air delivery. If you’ve ever been frustrated by a slow compressor, a double-acting model might be the solution.

These compressors are ideal for industrial settings where continuous, high-demand air supply is crucial. They tend to be larger and more robust, capable of handling demanding tasks. Imagine the smooth operation in a factory setting, where efficiency is key. Do you need more power and speed in your operations?

Choosing between single-acting and double-acting compressors can feel like picking the right tool for the job. It’s about understanding your needs and matching them with the compressor’s capabilities. So, what tasks are you looking to tackle with your air compressor?

Credit: www.airpressa.com

Rotary Screw Compressors

Rotary Screw Compressors are powerful, efficient machines commonly used in industrial settings. They operate using two interlocking screws to compress air, offering a continuous and reliable air supply. These compressors are especially valued for their durability and low maintenance needs, making them a favorite for many businesses. If you’re considering investing in a rotary screw compressor, understanding the differences between oil-injected and oil-free models can significantly impact your decision.

Oil-injected

Oil-injected rotary screw compressors are the workhorses of the industry. They use oil to lubricate, seal, and cool the compressor screws, enhancing the machine’s efficiency. This type of compressor is known for its robustness and ability to handle demanding tasks.

The presence of oil provides superior cooling and lubrication, which can extend the life of the compressor. However, the oil needs regular changing, which adds to maintenance requirements. If your operations can tolerate some oil in the air, this might be the more economical choice.

Imagine using an oil-injected compressor in a bustling factory. It works tirelessly, day in and day out, making sure your production lines keep moving. But remember, the oil might require filtration if your application demands pristine air.

Oil-free

Oil-free rotary screw compressors offer a different set of advantages. These machines are designed to produce 100% oil-free air, making them ideal for industries where air purity is crucial, such as pharmaceuticals or food and beverage production. They eliminate the risk of oil contamination, which can be a critical factor in sensitive environments.

Without oil, these compressors rely on other methods for cooling and sealing, which might result in slightly higher energy consumption. Yet, the peace of mind they offer in maintaining air purity can outweigh these costs.

Picture a scenario where you’re producing delicate food products. An oil-free compressor ensures that no oil particles mix with your ingredients, safeguarding the quality of your output. This assurance can be crucial when your brand’s reputation is on the line.

So, which one is right for you? Consider the nature of your operations and the importance of air purity. Would you prioritize low maintenance costs, or is air quality your top concern? By weighing these factors, you can make a more informed decision for your business.

Centrifugal Compressors

Centrifugal compressors are a type of air compressor that uses rotating impellers to increase air pressure. Known for high flow rates and efficiency, they are ideal for industrial applications requiring continuous airflow. These machines are different from other compressors like reciprocating and rotary screw, offering unique advantages in specific settings.

Centrifugal compressors are a fascinating piece of machinery that play a crucial role in various industries. They are designed to convert kinetic energy into pressure energy using a rotating impeller. Unlike other types of compressors, centrifugal compressors are known for their high efficiency and ability to handle large volumes of air or gas.

Multi-stage

Multi-stage centrifugal compressors are perfect for applications requiring high pressure. They use several impellers in sequence to gradually increase the pressure of the compressed air.

Each stage adds to the total pressure, making them ideal for tasks like gas turbines or chemical processing.

Have you ever wondered how industries manage to compress gas to such high pressures? Multi-stage compressors are the answer.

Single-stage

Single-stage centrifugal compressors, on the other hand, are simpler and more suited for applications where moderate pressure is sufficient. They feature just one impeller to compress the air.

These compressors are often used in situations where the demand for pressure is not as extreme, such as in HVAC systems or refrigeration.

Imagine your home air conditioner working efficiently all summer long; that’s a single-stage compressor at work.

Credit: www.aavsales.com

Axial Compressors

Axial compressors are a key type of air compressor, often used in jet engines and power plants. They efficiently increase air pressure by passing it through rotating blades. This design makes them ideal for high-flow applications.

Axial compressors are crucial in various industries. They are known for their high-speed operations and efficiency. Unlike other compressors, axial types use rotating blades to compress air. This makes them suitable for applications requiring continuous airflow.

Industrial Uses

Axial compressors are integral in aerospace. They are used in jet engines to compress air before combustion. Power plants also rely on them for efficient electricity generation. In oil and gas industries, they help in the processing and transportation of natural gas. Manufacturing sectors use axial compressors for large-scale air supply systems.

Efficiency Factors

The design of axial compressors impacts their efficiency. Blade shape and angle are vital for optimal air compression. The number of stages in a compressor affects its performance. More stages usually mean better compression ratios. Regular maintenance ensures they operate at peak efficiency. Proper alignment of components enhances their effectiveness.

Scroll Compressors

Scroll compressors are popular in the world of air compression. They are known for their efficiency and reliability. These compressors use a unique mechanism to compress air, offering several benefits.

Design Characteristics

Scroll compressors have a spiral design. This design involves two interlocking scrolls. One scroll remains stationary while the other moves. The moving scroll compresses the air gradually. This continuous motion reduces noise and vibrations. Scroll compressors have fewer moving parts. This minimizes the risk of mechanical failure. Their compact design saves space and is easy to install.

Performance Advantages

Scroll compressors operate quietly. This makes them suitable for noise-sensitive environments. They deliver consistent airflow without pulsations. This ensures smooth operation of connected equipment. Their efficiency reduces energy consumption, saving costs. Scroll compressors require less maintenance. Their simple design results in fewer breakdowns. They have a long lifespan and provide reliable service.

Portable Compressors

Portable compressors come in various types, including rotary screw, reciprocating, and centrifugal. Each type offers unique benefits for different tasks, from inflating tires to powering tools. Their compact design makes them ideal for convenient use in diverse settings, ensuring efficiency and versatility.

Portable compressors are incredibly versatile tools, cherished for their convenience and adaptability. Whether you’re an avid DIYer or a professional on the move, these compressors can make your tasks more efficient and manageable. They come in various shapes and sizes, each designed to cater to specific needs, making them an essential addition to your toolkit.

Applications

Portable compressors are perfect for a range of tasks, from inflating tires to powering air tools. Imagine you’re on a road trip, and your car tire suddenly needs air. A portable compressor can save the day, allowing you to quickly inflate your tire and get back on track.

They are also handy for small paint jobs around the house or for cleaning dust out of electronics. Their compact size and ease of use make them ideal for quick fixes and light-duty tasks.

Power Sources

Understanding the power source of a portable compressor is crucial for selecting the right one. Many portable compressors run on electricity, making them suitable for environments where a power outlet is available. They’re perfect for home garages or workshops.

However, if you’re often on the go or work in remote areas, a battery-powered or gas-powered compressor might be more suitable. These options offer the freedom to operate without needing a direct power supply. Consider what fits your lifestyle better.

Have you ever considered how a portable compressor could simplify your projects or adventures? With the right one, you can tackle unexpected challenges with ease.

Choosing The Right Compressor

Selecting the ideal air compressor involves understanding various types available, such as piston, rotary screw, and centrifugal. Each type offers unique benefits for different tasks. Evaluating your specific needs helps in choosing the most efficient and cost-effective option.

Choosing the right air compressor can be challenging. Many types and specifications exist. Picking the right one is crucial for efficiency. Consider several factors before making a decision.

Capacity Needs

Determine the air compressor’s capacity first. Assess the tasks it will handle. Smaller tasks require less power. Larger tasks demand more capacity. Match the compressor’s power with your needs. Avoid overestimating or underestimating requirements. This ensures efficiency and saves energy.

Maintenance Requirements

Consider the maintenance needs of the compressor. Some require frequent checks. Others need occasional servicing. Choose a model that fits your maintenance ability. Regular upkeep extends the compressor’s lifespan. It also ensures consistent performance. Check for user-friendly maintenance features. These can simplify the process.

Credit: sprsunheatpump.com

Frequently Asked Questions

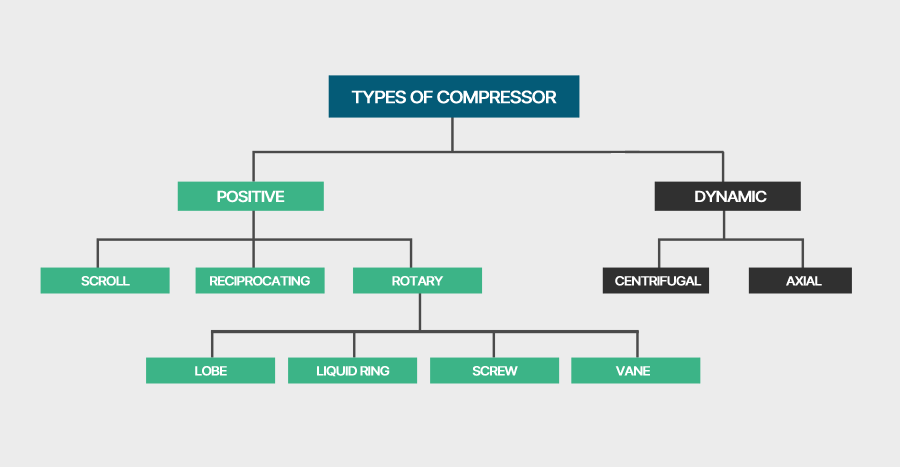

What Are The 4 Most Common Air compressors?

The four most common air compressors are reciprocating, rotary screw, centrifugal, and axial compressors. Each type serves different industrial and commercial needs, offering varied performance and efficiency levels. Choose based on your specific requirements, considering factors like power, capacity, and maintenance needs.

What Are The Three Main Types Of Air Compressors?

The three main types of air compressors are reciprocating, rotary screw, and centrifugal compressors. Each type has unique mechanisms and applications. Reciprocating compressors use pistons, rotary screw compressors use helical screws, and centrifugal compressors utilize a rotating impeller. These compressors serve various industrial and commercial needs efficiently.

What Is The Most Commonly Used Compressor?

The most commonly used compressor is the reciprocating compressor. It is popular for its efficiency and versatility. These compressors are widely used in various industries, including HVAC, refrigeration, and gas processing. Their ability to handle high pressures and different gases makes them a preferred choice.

Conclusion

Understand each type’s function. Reciprocating compressors suit small tasks. Rotary compressors handle continuous work. Centrifugal compressors fit large industrial needs. Always check power, size, and efficiency. Maintenance is crucial for long life.

Compare brands and read reviews. Keep safety in mind when using. Investing in a quality compressor saves time and effort. Make an informed decision. Your tasks will run smoothly with the right choice. Each type brings unique benefits. Pick wisely for the best results in your projects.